Today, the stone industry is booming. From rough material mining to fine processing and then to finished product manufacturing, every link has extremely high requirements for the efficiency and safety of handling and operation. In the past, stone handling mainly relied on manpower, which was not only inefficient but also accompanied by high safety risks, greatly restricting the development of the industry.

The emergence of Slab Lifter has completely changed this situation. As a device designed specifically for stone handling, Slab Lifter breaks through the limitations of traditional manual handling with its powerful mechanical properties. It uses advanced hydraulic or pneumatic systems to easily lift and accurately transport various types of stone, which is like injecting powerful power into the development of the stone industry.

For this reason, in-depth exploration of the reasons why Slab Lifter is indispensable in the stone industry is of great significance to understanding the development trend of the industry and improving production efficiency.

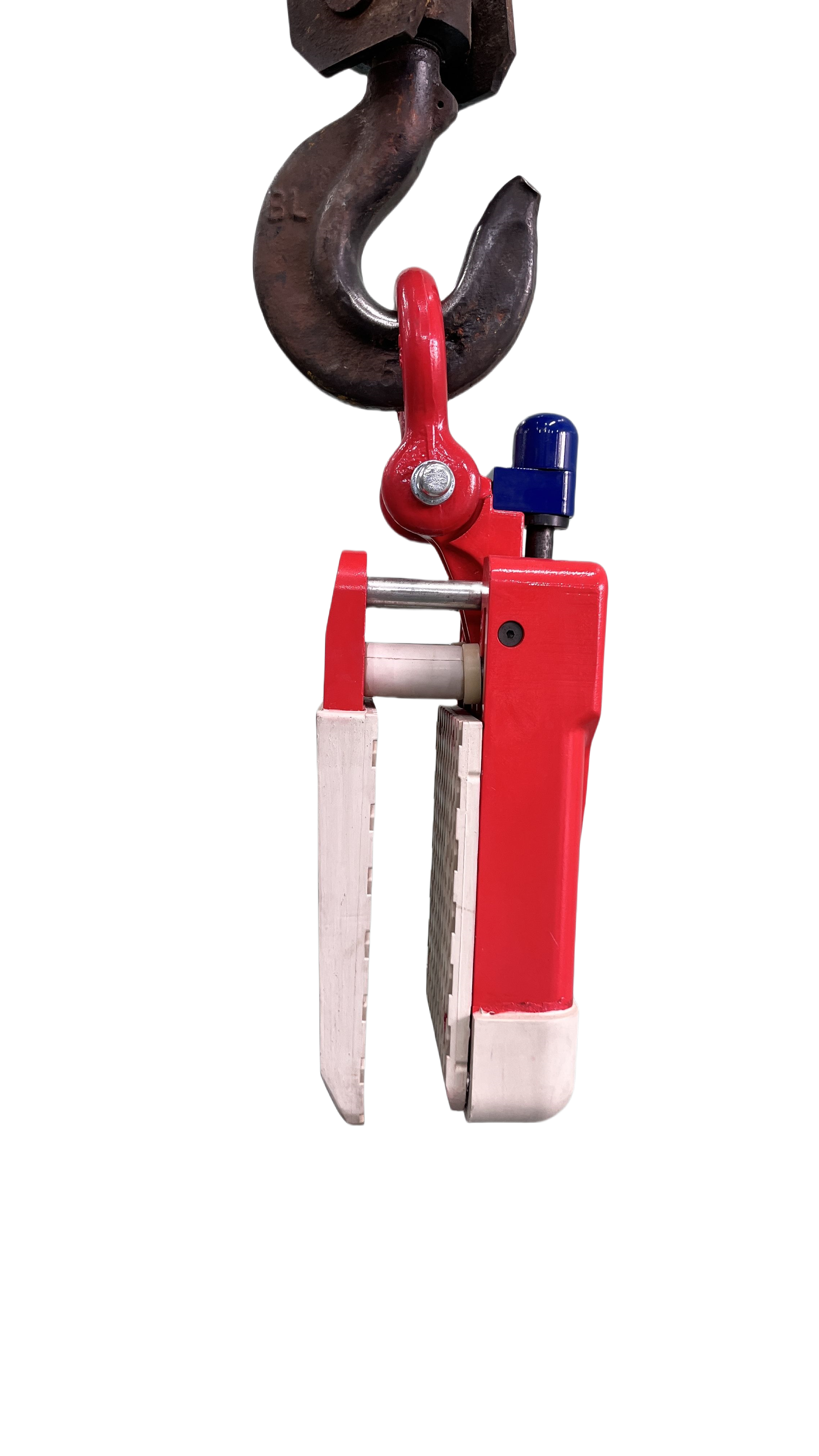

Slate tile lifting clamp

1. Swift and Precise Stone Handling for Efficiency

In a stone – processing yard, time is money. Manual labor for moving large stone slabs used to be a major bottleneck. Workers would struggle to shift heavy granite or marble slabs, often taking hours just to position a single piece. But slab lifters have changed this situation completely. With their high – torque hydraulic systems, these lifters can quickly grab and transport stone slabs.

For example, in a busy marble – cutting workshop, a slab lifter can move a dozen marble slabs from the storage area to the cutting machines in an hour. This kind of speed not only gets more work done in a day but also helps in meeting tight project deadlines.

2. Safety – First Approach in a High – Risk Environment

The stone industry is fraught with risks when it comes to handling heavy materials. Without slab lifters, workers are at a high risk of severe injuries. Back problems are common due to the constant strain of lifting heavy stones, and there’s always the danger of slabs slipping and causing crushing injuries.

Slab lifters mitigate these risks. They are equipped with advanced anti – slip gripping mechanisms and stable lifting arms. Operators can control the lifter from a safe distance, using joysticks or remote controls. This way, the chance of accidents is greatly reduced, making the workplace much safer for everyone involved.

3. Tailored for Diverse Stone Types and Sizes

Stone comes in all shapes, sizes, and densities. From the smooth and brittle limestone to the dense and tough basalt, each type requires careful handling. Slab lifters are designed with versatility in mind. Their adjustable gripping systems can be customized to fit different stone thicknesses and surface textures. A small – scale artisanal stone – carving studio might use a lightweight slab lifter with soft – touch grippers to handle delicate sandstone carvings.

In a large – scale granite quarry, on the other hand, heavy – duty slab lifters with extra – strong jaws are used to move massive granite blocks. This adaptability makes slab lifters suitable for every aspect of the stone industry.

4. Cost – Effective in the Long Run for Stone Businesses

The upfront cost of a slab lifter might seem like a significant investment. But when you calculate the long – term savings, it’s clear that it’s a smart financial move. By using slab lifters, stone companies can reduce their reliance on a large workforce for manual labor.

Fewer workers mean lower labor costs. Moreover, the reduced risk of workplace accidents leads to lower insurance premiums. And because slab lifters can handle stones more efficiently, there’s less waste of valuable stone materials. Over time, these savings far outweigh the initial purchase price of the slab lifter.

5. Paving the Way for Advanced Stone Processing

As technology marches forward, slab lifters in the stone industry are also evolving. Newer models are being integrated with smart technology. For example, some slab lifters now have built – in sensors that can detect the weight and density of the stone slab being lifted, adjusting the lifting force accordingly. This not only improves the safety of the operation but also enables more precise handling.

In the future, we can expect slab lifters to be even more automated, perhaps with self – driving capabilities within the stone yard. These advancements will further revolutionize the stone – processing industry, making it more efficient and productive.

Horizontal Stone Lifter Clamp

In conclusion, slab lifters have become an essential part of the stone industry. Their ability to boost efficiency, enhance safety, handle diverse stone materials, save costs, and drive innovation makes them a must – have for any business involved in stone processing, from quarries to finish – product manufacturers.

Henry

Hi, I’m the author of this post, and I have been in this field for more than 16 years. If you need OEM&ODM service for stone tools, feel free to ask me any questions.